When investing in a 3D printer, it’s essential to consider its lifespan and longevity. After all, understanding how long a 3D printer can last helps users gauge its durability, cost-effectiveness, and overall value. In this article, we will explore the factors that influence the lifespan of 3D printers, maintenance tips to extend their longevity, and some common signs indicating when it might be time for a replacement.

How Long Do 3D Printers Last?

The lifespan of a 3D printer can vary significantly based on several factors. Here are the key elements that determine how long a 3D printer typically lasts:

1. Build Quality

The build quality of a 3D printer plays a crucial role in determining its lifespan. High-quality printers with robust frames and durable components tend to last longer than cheaper, lower-quality alternatives. When purchasing a 3D printer, it’s essential to consider the materials used, customer reviews, and the reputation of the manufacturer.

2. Usage Frequency

The frequency of use directly impacts a 3D printer’s lifespan. Continuous and intensive usage, such as in a commercial setting, can put more strain on the printer’s components and reduce its overall lifespan. However, if used sparingly, a 3D printer can last significantly longer.

3. Maintenance and Care

Proper maintenance and care significantly contribute to extending the lifespan of a 3D printer. Regular cleaning, lubrication, and calibration are essential to keep the printer in optimal condition. Adhering to manufacturer guidelines for maintenance and handling can help prevent premature wear and tear.

4. Technology Advancement

Technological advancements in 3D printing can also influence the lifespan of a printer. As technology evolves, older models may become outdated or lack support for new software and materials. While the printer itself may still function, the lack of compatibility and software updates can limit its usefulness over time.

Maintenance Tips for Extending 3D Printer Lifespan

To maximize the lifespan of your 3D printer, follow these maintenance tips:

- Regular Cleaning: Clean the printer’s extruder, build plate, and nozzle regularly to prevent clogs and maintain optimal printing performance. Refer to the manufacturer’s guidelines for proper cleaning techniques.

- Lubrication: Apply lubricant to moving parts, such as rods and bearings, as recommended by the manufacturer. This reduces friction and extends the lifespan of these components.

- Calibration: Regularly calibrate the printer to ensure accurate prints and prevent strain on the components. Calibration helps maintain the printer’s precision and reliability.

- Filament Quality: Use high-quality filament to minimize clogs and reduce strain on the printer’s extruder. Inferior filament can cause nozzle blockages and affect the overall performance of the printer.

- Temperature Control: Operate the printer within the recommended temperature range. Extreme temperatures can adversely affect the printer’s components and reduce their lifespan.

- Proper Storage: When not in use, store the printer in a clean and dust-free environment. Protect it from exposure to moisture and direct sunlight, as these can damage sensitive components.

Signs It’s Time for a Replacement

While proper maintenance can extend the lifespan of a 3D printer, there may come a time when a replacement is necessary. Here are some signs indicating it might be time to invest in a new printer:

- Irreparable Damage: If the printer sustains severe damage that cannot be repaired economically, it might be more cost-effective to purchase a new one.

- Outdated Technology: If the printer becomes incompatible with new software updates or lacks support for the latest printing materials, it may limit your ability to take advantage of advancements in 3D printing technology.

- Frequent Breakdowns: If the printer experiences frequent malfunctions or breakdowns, despite proper maintenance, it may be an indication of age-related wear and tear.

- Limited Print Quality: As the printer ages, it may struggle to maintain the same level of print quality it once achieved. If you require consistently high-quality prints, upgrading to a newer model might be necessary.

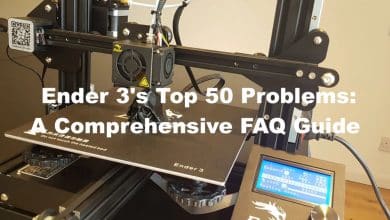

FAQ

1. How often should I clean my 3D printer?

Cleaning your 3D printer is crucial for maintaining its optimal performance. The frequency of cleaning depends on your usage and the type of printer you have. As a general guideline, it is recommended to clean your printer after every few prints or when you notice any signs of debris or residue buildup. Cleaning involves removing dust, filament particles, and other contaminants that can affect print quality and clog the printer’s components. By keeping your printer clean, you can prevent potential issues and ensure consistent, high-quality prints.

2. Can I use any filament with my 3D printer?

Not all 3D printers are compatible with every type of filament. The filament compatibility depends on the printer’s specifications and the type of extruder it uses. Some printers are designed to work specifically with certain filament materials such as PLA, ABS, or PETG, while others have a wider range of compatibility. It is essential to check the manufacturer’s guidelines or specifications to determine the filaments suitable for your printer. Using an incompatible filament can lead to poor print quality, clogs, and even damage to the printer’s extruder.

3. How do I troubleshoot common 3D printing issues?

When encountering common 3D printing issues like stringing, warping, or failed prints, there are several troubleshooting steps you can take. Firstly, ensure that your printer’s bed is properly leveled and that the nozzle-to-bed distance is correctly set. Additionally, check that your filament is loaded correctly and that the extruder is extruding consistently. Adjusting print settings such as temperature, speed, and retraction can also help address specific issues. If problems persist, referring to online resources, forums, or contacting the manufacturer’s customer support can provide valuable guidance for troubleshooting your specific printer model.

4. How can I improve the print quality of my 3D printer?

To enhance the print quality of your 3D printer, there are a few key factors to consider. Firstly, ensure that your printer is properly calibrated, including the extruder steps per millimeter, bed leveling, and belt tension. Secondly, optimize your print settings by adjusting parameters such as layer height, infill density, and print speed to achieve the desired level of detail and strength. Using high-quality filaments and ensuring they are stored correctly can also positively impact print quality. Additionally, utilizing support structures when necessary and experimenting with different slicer software settings can help improve specific aspects of print quality, such as overhangs or bridging.

5. Can I upgrade or replace components in my 3D printer?

In many cases, components in 3D printers can be upgraded or replaced, allowing users to enhance performance or address specific needs. Common components that can be upgraded include the extruder, hotend, heated bed, and control board. Upgrading these components can result in improved print quality, faster printing speeds, or compatibility with a broader range of filaments. It is important to ensure that any upgrades or replacements are compatible with your specific printer model and to follow manufacturer guidelines or seek professional assistance when making modifications.

6. Are 3D printers noisy?

The level of noise produced by a 3D printer can vary depending on factors such as the printer’s design, the type of motors used, and the materials being printed. While some printers operate relatively quietly, others may generate more noticeable noise due to motor vibrations or cooling fans. Enclosing the printer with sound-dampening materials or placing it in a separate, well-ventilated space can help reduce noise levels. Additionally, selecting printers with quieter stepper motors or opting for printers with advanced noise reduction features can also minimize the overall noise output during printing.

7. Can I leave my 3D printer unattended while printing?

Leaving a 3D printer unattended while printing is generally not recommended. While modern 3D printers are designed with safety features, there is still a small risk of mechanical failures or malfunctions that can lead to accidents or damage. It is crucial to monitor the printing process to ensure that the printer is operating correctly, filament is feeding properly, and there are no signs of overheating or other issues. If you need to leave the printer for an extended period, it is advisable to pause the print and resume it once you can provide adequate supervision.

Conclusion

Understanding the lifespan of a 3D printer and implementing proper maintenance practices is essential for maximizing its longevity. By investing in a high-quality printer, following maintenance guidelines, and being aware of signs that indicate the need for a replacement, users can ensure they get the most value from their 3D printing investment. Remember, a well-maintained printer can serve you for years to come, providing endless possibilities for creativity and innovation.