3D printing, also known as additive manufacturing, has become increasingly popular in recent years due to its ability to produce highly customized and complex objects with relative ease. From creating prototypes for product development to producing intricate works of art, the possibilities of 3D printing are endless. However, as with any new technology, many people have questions about how it works, its potential applications, and its impact on various industries. This guide aims to answer 100 of the most common questions about 3D printing, providing readers with a comprehensive understanding of this fascinating technology.

Throughout this guide, we will explore the basics of 3D printing, including how it works and the different types of 3D printing processes. We will also delve into the various applications of 3D printing, from creating living organs to improving the efficiency of agriculture. Additionally, we will discuss the impact of 3D printing on various industries, including fashion, automotive, and robotics. Whether you are a curious hobbyist or a seasoned professional, this guide has something to offer.

100 Frequently Asked Questions : 3D Printing Explained

1. What is 3D printing?

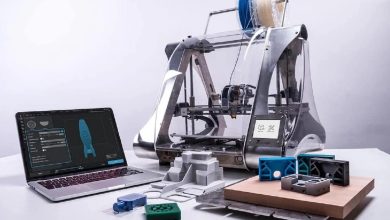

3D printing is a process of creating three-dimensional physical objects from a digital model or CAD file. This process is also known as additive manufacturing, as it builds objects layer by layer. The 3D printer uses a variety of materials such as plastic, metal, or even living cells to create the object. 3D printing is a highly precise and customizable process that has many applications across different industries such as aerospace, medical, and automotive.

2. How does 3D printing work?

3D printing works by creating an object from a digital model through an additive process. First, the 3D model is created using a software program such as CAD. This model is then sliced into layers, and the 3D printer reads the digital file and prints the object layer by layer. The 3D printer deposits the material onto the build platform based on the instructions in the digital file. The material is melted, cured, or sintered to form the object. Once the first layer is complete, the build platform moves down, and the next layer is printed on top of the previous one. This process repeats until the entire object is printed.

3. What are the different types of 3D printers?

There are several different types of 3D printers, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP). FDM is the most common type and uses melted plastic filament to build the object layer by layer. SLA uses a liquid resin that is cured by a laser to create the object. SLS uses a powder material that is sintered together by a laser to create the object. DLP is similar to SLA but uses a projector to cure the resin.

4. What is the difference between FDM and SLA printing?

The main difference between FDM and SLA printing is the way they create the object. FDM uses melted plastic filament that is extruded through a nozzle onto the build platform. The plastic is deposited layer by layer to create the object. SLA, on the other hand, uses a liquid resin that is cured by a laser. The laser creates the object by curing the resin layer by layer. SLA printing is generally more precise and produces smoother surfaces, while FDM printing is faster and can use a wider range of materials.

5. What is the difference between ABS and PLA materials?

ABS and PLA are two of the most commonly used materials in 3D printing. ABS is a thermoplastic polymer that is strong and durable, making it ideal for printing objects that need to withstand high stress or impact. It has a high melting point and can be difficult to print without warping or cracking. PLA is also a thermoplastic polymer but is made from renewable resources such as corn starch or sugarcane. It is easier to print than ABS and produces less odor and fumes. PLA is not as strong as ABS and may deform in high-temperature environments.

6. What is the maximum size of an object that can be printed using a 3D printer?

The maximum size of an object that can be printed using a 3D printer depends on the size of the build platform and the printer’s design. Some consumer-grade printers have a build volume of around 200mm x 200mm x 200mm, while industrial printers can print objects up to several meters in size. Large objects may need to be printed in multiple parts and assembled afterward.

7. What is the minimum layer thickness that can be achieved using a 3D printer?

The minimum layer thickness that can be achieved using a 3D printer depends on the printer’s capabilities and the material used. Most consumer-grade 3D printers have a minimum layer thickness of around 0.1mm, while some industrial-grade printers can achieve layer thicknesses as low as 0.01mm. However, printing with thinner layers can increase the printing time and may require more precision in the printer’s hardware.

8. What are the advantages of 3D printing?

One of the main advantages of 3D printing is the ability to create complex and customized objects with a high level of precision. 3D printing is also a cost-effective manufacturing method, as it reduces waste and enables the production of small batches. 3D printing is a versatile process that can use a variety of materials, including plastics, metals, and even living cells. Additionally, 3D printing can shorten the design and prototyping phase and enable rapid product development.

9. What are the disadvantages of 3D printing?

One of the main disadvantages of 3D printing is the limited size and resolution of the printed objects. 3D printing can also be a slow process, especially when printing large or complex objects. Additionally, 3D printing may require a significant investment in equipment and software. Some 3D printing materials may also produce harmful fumes or require specialized handling. Finally, 3D printing may not be suitable for mass production, as it may not be as cost-effective as other manufacturing methods.

10. Can 3D printers print in multiple colors?

Yes, some 3D printers can print in multiple colors by using multiple extruders or by changing the filament during the printing process. However, not all 3D printers are capable of multi-color printing, and it may require additional hardware or software to achieve.

11. What file formats are used for 3D printing?

The most common file format used for 3D printing is STL (STereoLithography), which represents a 3D model as a series of triangles. Other file formats commonly used for 3D printing include OBJ, AMF, and 3MF. Some 3D printers may also support other file formats or require proprietary file formats specific to the printer’s software.

12. What is G-code?

G-code is a programming language used by 3D printers to control the movements of the printer’s extruder and build platform. G-code commands specify the printer’s speed, position, and extrusion rate, among other parameters. G-code is generated from the 3D model and sliced into layers to create the digital file that the 3D printer reads.

13. How do you create a 3D model for printing?

There are several ways to create a 3D model for printing. One way is to use a CAD (Computer-Aided Design) software program, which allows the user to create a 3D model from scratch or modify an existing model. Another way is to use a 3D scanner, which can create a digital model from a physical object. Finally, some websites offer a library of 3D models that can be downloaded and modified for printing.

14. What software is used for 3D printing?

Several software programs are used for 3D printing, including CAD software for creating 3D models, slicers for converting 3D models into G-code, and printer management software for controlling the printer and monitoring the printing process. Some popular CAD software programs include Autodesk Fusion 360, SolidWorks, and SketchUp. Slicing software includes Ultimaker Cura, PrusaSlicer, and Simplify3D. Printer management software includes OctoPrint, Repetier-Server, and AstroPrint.

15. Can 3D printers print flexible materials?

Yes, some 3D printers can print flexible materials such as TPU (Thermoplastic Polyurethane) or TPE (Thermoplastic Elastomer). These materials have a rubber-like texture and can be used to print objects such as phone cases, watch straps, or shoe soles. However, printing with flexible materials can be more challenging than printing with rigid materials and may require adjustments to the printer’s settings.

16. Can 3D printers print with metal?

Yes, some 3D printers can print with metal by using a process called Metal 3D Printing or Additive Manufacturing. This process uses metal powder or wire that is melted and fused together layer by layer to create the object. Metal 3D printing can create objects with high strength and durability, making it ideal for industrial applications such as aerospace and automotive manufacturing.

17. What is the accuracy of 3D printing?

The accuracy of 3D printing depends on several factors, including the printer’s hardware, the printing material, and the complexity of the object being printed. Most consumer-grade 3D printers have an accuracy of around 0.1mm to 0.2mm, while industrial-grade printers can achieve an accuracy of 0.01mm or better. Additionally, the accuracy of 3D printing can be affected by factors such as warping, shrinkage, and distortion.

18. How long does it take to print an object using a 3D printer?

The time it takes to print an object using a 3D printer depends on several factors, including the size and complexity of the object, the layer thickness, and the printing speed. Small and simple objects may only take a few hours to print, while larger and more complex objects can take several days or even weeks to print. Additionally, printing with thinner layers can increase the printing time, but it can also improve the object’s quality.

19. What is the cost of a 3D printer?

The cost of a 3D printer can vary widely depending on the printer’s capabilities and the intended use. Consumer-grade 3D printers can range from a few hundred dollars to several thousand dollars, while industrial-grade 3D printers can cost hundreds of thousands of dollars or more. Additionally, the cost of materials, maintenance, and upgrades should be considered when purchasing a 3D printer.

20. How long do 3D printers last?

The lifespan of a 3D printer can vary depending on the printer’s quality, frequency of use, and maintenance. Consumer-grade 3D printers typically have a lifespan of around 2-3 years, while industrial-grade 3D printers can last for a decade or more with proper maintenance and upgrades.

21. What safety precautions should be taken while using a 3D printer?

Some safety precautions should be taken while using a 3D printer, including wearing gloves and safety glasses when handling materials and avoiding inhaling any fumes or particles that may be emitted during the printing process. Additionally, the printer should be placed in a well-ventilated area, and the user should be aware of any potential fire hazards.

22. Can 3D printers be used for commercial purposes?

Yes, 3D printers can be used for commercial purposes, and many businesses use 3D printing for prototyping, tooling, and production of customized parts. 3D printing can also be used for creating complex geometries that are difficult or impossible to produce with traditional manufacturing methods. However, 3D printing may not be suitable for mass production or high-volume manufacturing, as it may not be as cost-effective as other manufacturing methods.

23. What is the environmental impact of 3D printing?

The environmental impact of 3D printing can vary depending on the materials used, the printer’s energy consumption, and the disposal of waste materials. 3D printing can reduce waste by producing only the necessary amount of material and reducing the need for transportation. However, some 3D printing materials may be non-biodegradable or produce harmful emissions during the printing process. Additionally, 3D printing may require a significant amount of energy to operate, especially for industrial-grade printers.

24. Can 3D printers be used to create medical implants?

Yes, 3D printing can be used to create customized medical implants such as dental implants, hearing aids, or prosthetic limbs. 3D printing can create implants that are more precise and accurate than traditional manufacturing methods, and can be customized to fit a patient’s specific anatomy. Additionally, 3D printing can reduce the production time and cost of medical implants.

25. Can 3D printing be used for creating replacement parts for machines?

Yes, 3D printing can be used to create replacement parts for machines, especially for machines that are no longer in production or have specialized parts. 3D printing can create parts that are difficult or impossible to obtain through traditional manufacturing methods, and can be customized to fit the machine’s specifications. Additionally, 3D printing can reduce the lead time and cost of producing replacement parts. However, the strength and durability of 3D-printed parts may not be as high as traditional parts, and they may require additional testing and certification.

26. Can 3D printing be used for creating customized toys?

Yes, 3D printing can be used to create customized toys. 3D printing allows the creation of unique designs that can be printed on demand. The technology enables designers and consumers to create toys that are not available in stores, resulting in a personalized experience.

One example is the use of 3D printing to create custom action figures. Customers can provide a design or a 3D model, and the toy can be printed in different sizes and materials. Another example is the creation of customized puzzles, where customers can design the puzzle’s shape and size, add their images, and have them printed in 3D.

Moreover, 3D printing also allows designers to create toys that have intricate details and movable parts, which are difficult to produce using traditional manufacturing methods. Therefore, 3D printing is an excellent tool for toy makers to produce custom toys that cater to their customer’s preferences.

27. Can 3D printing be used for creating jewelry?

Yes, 3D printing is an increasingly popular technology for creating jewelry. 3D printing allows designers to create complex and intricate designs that are not possible to achieve using traditional manufacturing methods. With 3D printing, designers can create designs on computer-aided design (CAD) software and print them in various materials such as precious metals, resins, and even food-grade materials.

The process of creating jewelry using 3D printing involves the use of a 3D modeling software to create the design, which is then printed using a 3D printer. The printed jewelry is then post-processed, which includes polishing, plating, and adding stones to the final product.

3D printing also enables the creation of custom jewelry pieces that cater to individual preferences. Customers can provide their designs, and jewelers can 3D print the piece, resulting in a personalized experience. Overall, 3D printing has revolutionized the jewelry-making industry, allowing designers to create unique, customized pieces at a faster rate and lower cost than traditional methods.

28. Can 3D printing be used for creating prosthetics?

Yes, 3D printing has been used extensively in the creation of prosthetics. Traditional prosthetic manufacturing methods are costly and time-consuming, making it difficult for people with limb differences to access prosthetics. However, 3D printing has made prosthetic manufacturing more accessible and affordable.

Using 3D printing, prosthetic limbs can be created using a 3D scan of the residual limb, resulting in a personalized prosthetic that fits the individual’s limb perfectly. Moreover, 3D printing allows the creation of prosthetics with intricate designs and custom features, such as 3D printed fingers that can move and grasp objects.

Additionally, 3D printing has enabled the creation of low-cost prosthetics, making it possible for people in developing countries to access prosthetics. The technology has also made it easier to repair and replace prosthetic parts as needed. Overall, 3D printing has revolutionized the prosthetic industry, making it more accessible and personalized for those who need it.

29. Can 3D printing be used for creating musical instruments?

Yes, 3D printing can be used to create musical instruments. The technology allows the creation of custom and unique instruments with intricate designs, shapes, and structures. 3D printing has been used to create guitars, violins, and even a 3D printed saxophone.

3D printing enables the production of complex shapes that are not possible with traditional manufacturing methods, allowing for unique and innovative instrument designs. Moreover, 3D printing can produce instruments with high accuracy and consistency, resulting in better sound quality and performance.

Another benefit of using 3D printing for musical instruments is the ability to create lightweight and portable instruments. For example, 3D printed guitars are much lighter than traditional guitars, making them easier to carry around for musicians who travel frequently.

Furthermore, 3D printing has made it easier and more affordable for musicians to experiment with instrument design and customization. Musicians can create custom parts for their instruments, such as guitar pickups, using 3D printing, resulting in a personalized instrument and sound. Overall, 3D printing has revolutionized the music industry by providing musicians with the ability to create unique, personalized, and high-quality instruments.

30. Can 3D printing be used for creating architectural models?

Yes, 3D printing is an excellent tool for creating architectural models. Traditional methods of creating architectural models can be time-consuming and expensive. However, 3D printing allows architects to create accurate and detailed models quickly and at a lower cost.

With 3D printing, architects can create models that show intricate details, including textures, facades, and structural elements. Additionally, 3D printing allows architects to create scaled models, making it easier to visualize and present the final design to clients and stakeholders.

Moreover, 3D printing enables the creation of custom and unique architectural models that cater to individual preferences. Architects can create models in different materials and colors, allowing clients to see the building’s design in various contexts and environments.

Overall, 3D printing has revolutionized the architectural industry by providing architects with a faster and more cost-effective method of creating detailed and accurate models, allowing for better visualization and communication of the design to stakeholders.

31. Can 3D printing be used for creating food?

Yes, 3D printing can be used for creating food. 3D printing allows chefs and food designers to create unique and intricate food designs, resulting in a personalized and customized culinary experience. The technology enables the creation of complex shapes and textures that are difficult to achieve using traditional cooking methods.

3D printing in the food industry involves using food-grade materials such as chocolate, cheese, and even dough to print various designs. The printing process can be customized, allowing chefs to create specific designs based on individual preferences and dietary requirements.

Moreover, 3D printing in the food industry can help address food waste issues by creating customized portions that match the individual’s appetite, reducing the amount of food waste. Additionally, 3D printing can help improve food safety by ensuring consistent portions and reducing the risk of contamination.

32. Can 3D printing be used for creating furniture?

Yes, 3D printing can be used for creating furniture. 3D printing allows designers to create unique and custom furniture designs that cater to individual preferences. The technology enables the creation of complex shapes and structures that are not possible using traditional manufacturing methods.

3D printing in furniture design involves using various materials such as plastic, wood, and metal to create the furniture pieces. The printing process allows designers to create intricate designs, including details such as texture and patterns.

3D printing can also help reduce waste in furniture production by enabling the creation of furniture pieces with less material waste. For example, 3D printing can create furniture with a lattice structure, reducing the amount of material used while maintaining structural integrity.

Additionally, 3D printing can make furniture production more sustainable by allowing designers to create furniture pieces on-demand, reducing the need for large production runs and excess inventory. This approach also allows for customization, allowing customers to personalize their furniture pieces based on their preferences.

33. Can 3D printing be used for creating sports equipment?

Yes, 3D printing can be used for creating sports equipment. The technology allows designers to create custom and unique designs that cater to individual preferences and enhance athletic performance.

3D printing has been used to create various sports equipment, including bike helmets, football cleats, and even a 3D printed kayak. The printing process enables the creation of lightweight and durable sports equipment with intricate designs and structures, improving performance and comfort for athletes.

Moreover, 3D printing can help reduce waste in sports equipment production by enabling the creation of products with less material waste. Additionally, 3D printing can reduce the time and cost of creating new sports equipment designs, allowing designers to create and test new designs more quickly.

34. Can 3D printing be used for creating clothing?

Yes, 3D printing can be used for creating clothing. The technology enables designers to create custom and unique designs that cater to individual preferences and can be printed on demand. 3D printing allows designers to create clothing with intricate details and complex shapes that are not possible using traditional manufacturing methods.

3D printing in clothing production involves using materials such as nylon and other flexible materials to create the clothing pieces. The printing process can be customized to create specific designs based on individual preferences, resulting in a personalized clothing experience.

Moreover, 3D printing can help reduce waste in clothing production by creating products with less material waste. Additionally, 3D printing can make clothing production more sustainable by allowing designers to create clothing on-demand, reducing the need for large production runs and excess inventory.

35. Can 3D printing be used for creating art?

Yes, 3D printing can be used for creating art. The technology enables artists to create intricate and unique art designs that are not possible using traditional methods. 3D printing allows artists to create complex shapes and structures, resulting in a personalized and customized art experience.

3D printing in the art industry involves using various materials such as plastic, metal, and even food-grade materials to create art pieces. The printing process allows artists to create intricate designs, including details such as texture and patterns.

Moreover, 3D printing can help reduce waste in art production by creating products with less material waste. Additionally, 3D printing can make art production more sustainable by allowing artists to create art pieces on-demand, reducing the need for large production runs and excess inventory.

Furthermore, 3D printing can also be used to recreate historical artifacts and sculptures, enabling artists to create exact replicas of ancient pieces that may be too fragile or expensive to transport. Additionally, 3D printing can create interactive and kinetic art pieces, allowing viewers to interact with the art in new and innovative ways.

36. Can 3D printing be used for creating tools?

Yes, 3D printing can be used for creating tools. The technology enables the creation of custom and unique tool designs that cater to specific needs and requirements. 3D printing allows the production of tools with intricate details and shapes that are not possible using traditional manufacturing methods.

3D printing in tool production involves using various materials such as metal, plastic, and even ceramics to create the tools. The printing process can be customized to create specific designs based on individual preferences, resulting in a personalized tool experience.

Moreover, 3D printing can help reduce waste in tool production by creating products with less material waste. Additionally, 3D printing can reduce the time and cost of creating new tool designs, allowing designers to create and test new designs more quickly.

37. Can 3D printing be used for creating machine parts?

Yes, 3D printing can be used for creating machine parts. The technology enables the creation of custom and unique machine parts that cater to specific needs and requirements. 3D printing allows the production of parts with intricate details and shapes that are not possible using traditional manufacturing methods.

3D printing in machine parts production involves using various materials such as metal, plastic, and even ceramics to create the parts. The printing process can be customized to create specific designs based on individual preferences, resulting in a personalized machine part experience.

Moreover, 3D printing can help reduce waste in machine part production by creating products with less material waste. Additionally, 3D printing can reduce the time and cost of creating new machine part designs, allowing designers to create and test new designs more quickly.

38. Can 3D printing be used for creating molds?

Yes, 3D printing can be used for creating molds. The technology allows the creation of custom and unique mold designs that cater to specific needs and requirements. 3D printing allows the production of molds with intricate details and shapes that are not possible using traditional manufacturing methods.

3D printing in mold production involves using various materials such as plastic, resin, and even metal to create the molds. The printing process can be customized to create specific designs based on individual preferences, resulting in a personalized mold experience.

Moreover, 3D printing can help reduce waste in mold production by creating products with less material waste. Additionally, 3D printing can reduce the time and cost of creating new mold designs, allowing designers to create and test new designs more quickly.

39. Can 3D printing be used for creating educational models?

Yes, 3D printing can be used for creating educational models. The technology enables the creation of accurate and detailed models that are not possible using traditional methods. 3D printing allows educators to create models that can help students visualize and understand complex concepts in various subjects, including science, history, and mathematics.

3D printing in educational model production involves using various materials such as plastic, resin, and even metal to create the models. The printing process can be customized to create specific designs based on individual preferences, resulting in a personalized educational model experience.

Moreover, 3D printing can help reduce waste in educational model production by creating products with less material waste. Additionally, 3D printing can make educational model production more sustainable by allowing educators to create models on-demand, reducing the need for large production runs and excess inventory.

40. Can 3D printing be used for creating architectural designs?

Yes, 3D printing can be used for creating architectural designs. The technology enables architects to create complex and unique designs that cater to individual preferences and can be printed on demand. 3D printing allows architects to create detailed and accurate models quickly and at a lower cost than traditional methods.

3D printing in architectural design involves using various materials such as plastic, metal, and even concrete to create the designs. The printing process can be customized to create specific designs based on individual preferences, resulting in a personalized architectural design experience.

Moreover, 3D printing can help reduce waste in architectural design by creating products with less material waste. Additionally, 3D printing can make architectural design production more sustainable by allowing architects to create designs on-demand, reducing the need for large production runs and excess inventory.

41. What is the future of 3D printing?

The future of 3D printing is promising, with advancements in technology and applications continuing to emerge. One of the main areas of growth for 3D printing is in the medical industry, where the technology is being used to create personalized medical devices and implants. 3D printing is also being used in the aerospace industry to create lightweight and complex parts that are not possible using traditional manufacturing methods.

Another area of growth for 3D printing is in the construction industry, where the technology is being used to create large-scale structures quickly and at a lower cost than traditional construction methods. The fashion industry is also embracing 3D printing, with designers using the technology to create unique and personalized clothing designs.

Advancements in 3D printing technology are also allowing for the use of new materials, such as living cells and biomaterials, to create tissue and organ replacements for medical purposes. The technology is also being used to create food, with the potential to revolutionize the food industry by providing customized nutrition solutions.

42. How has 3D printing impacted manufacturing?

3D printing has had a significant impact on manufacturing, revolutionizing the way products are designed and produced. One of the main benefits of 3D printing is the ability to create complex and customized designs quickly and at a lower cost than traditional manufacturing methods. This has allowed for greater innovation in product design, with products being created that were not possible using traditional manufacturing methods.

Additionally, 3D printing has enabled the creation of products on demand, reducing the need for large production runs and excess inventory. This approach has also allowed for greater customization, with products being tailored to individual preferences and needs.

Moreover, 3D printing has helped reduce waste in manufacturing by enabling the creation of products with less material waste. This has made manufacturing more sustainable and environmentally friendly.

43. What are the limitations of 3D printing?

While 3D printing has revolutionized various industries, there are still some limitations to the technology. One of the main limitations is the size of the objects that can be printed. While advancements in technology have enabled larger objects to be printed, there is still a limit to the size of objects that can be printed using current technology.

Another limitation is the materials that can be used for printing. While various materials can be used, including plastics, metals, and ceramics, some materials may not be suitable for printing or may be too expensive to use for larger production runs.

Additionally, the quality of the printed object may not always be as good as traditional manufacturing methods. This can be due to factors such as layering and the quality of the printing material used.

44. How can 3D printing be used in the aerospace industry?

3D printing has revolutionized the aerospace industry by enabling the creation of complex and lightweight parts that are not possible using traditional manufacturing methods. The technology allows for the production of intricate designs with high precision and accuracy, resulting in higher quality parts that are also more cost-effective.

Moreover, 3D printing has enabled the creation of custom and unique parts on demand, reducing the need for large production runs and excess inventory. This approach has also allowed for greater customization, with parts being tailored to individual requirements and preferences.

Furthermore, 3D printing has the potential to reduce waste in the aerospace industry by creating products with less material waste. The technology also enables the use of new materials, including lightweight and advanced materials, for aerospace parts production.

45. How can 3D printing be used in the automotive industry?

3D printing has had a significant impact on the automotive industry by enabling the creation of complex and customized parts that are not possible using traditional manufacturing methods. The technology allows for the production of intricate designs with high precision and accuracy, resulting in higher quality parts that are also more cost-effective.

Moreover, 3D printing has enabled the creation of custom and unique parts on demand, reducing the need for large production runs and excess inventory. This approach has also allowed for greater customization, with parts being tailored to individual requirements and preferences.

Furthermore, 3D printing has the potential to reduce waste in the automotive industry by creating products with less material waste. The technology also enables the use of new materials, including lightweight and advanced materials, for automotive parts production.

46. How can 3D printing be used in the healthcare industry?

3D printing has had a significant impact on the healthcare industry by enabling the creation of personalized medical devices and implants. The technology allows for the production of accurate and detailed models based on individual requirements and preferences, resulting in improved patient outcomes.

Moreover, 3D printing has enabled the creation of custom and unique prosthetics, implants, and surgical tools, reducing the need for standard or off-the-shelf products. This approach has also allowed for greater customization, with medical devices being tailored to individual requirements and preferences.

Furthermore, 3D printing has the potential to reduce waste in the healthcare industry by creating products with less material waste. The technology also enables the use of new materials, including living cells and biomaterials, for tissue and organ replacements.

47. How can 3D printing be used in the fashion industry?

3D printing has had a significant impact on the fashion industry by enabling designers to create unique and personalized clothing designs. The technology allows for the production of intricate and complex designs with high precision and accuracy, resulting in higher quality clothing that is also more cost-effective.

Moreover, 3D printing has enabled the creation of custom and unique clothing designs on demand, reducing the need for large production runs and excess inventory. This approach has also allowed for greater customization, with clothing being tailored to individual requirements and preferences.

Furthermore, 3D printing has the potential to reduce waste in the fashion industry by creating products with less material waste. The technology also enables the use of new materials, including sustainable and eco-friendly materials, for clothing production.

48. How can 3D printing be used in the art industry?

3D printing has had a significant impact on the art industry by enabling artists to create unique and personalized art pieces. The technology allows for the production of intricate and complex designs with high precision and accuracy, resulting in higher quality art pieces that are also more cost-effective.

Moreover, 3D printing has enabled the creation of custom and unique art pieces on demand, reducing the need for large production runs and excess inventory. This approach has also allowed for greater customization, with art pieces being tailored to individual requirements and preferences.

Furthermore, 3D printing has the potential to reduce waste in the art industry by creating products with less material waste. The technology also enables the use of new materials, including sustainable and eco-friendly materials, for art piece production.

49. How can 3D printing be used in the food industry?

3D printing has the potential to revolutionize the food industry by enabling the creation of customized and nutritious food products. The technology allows for the production of intricate and complex food designs with high precision and accuracy, resulting in higher quality food products that are also more cost-effective.

Moreover, 3D printing has enabled the creation of custom and unique food designs on demand, reducing the need for large production runs and excess inventory. This approach has also allowed for greater customization, with food being tailored to individual nutritional requirements and preferences.

Furthermore, 3D printing has the potential to reduce waste in the food industry by creating products with less material waste. The technology also enables the use of new ingredients, including alternative protein sources, for food production.

50. How can 3D printing be used in the construction industry?

3D printing has the potential to revolutionize the construction industry by enabling the creation of large-scale structures quickly and at a lower cost than traditional construction methods. The technology allows for the production of intricate and complex designs with high precision and accuracy, resulting in higher quality structures that are also more cost-effective.

Moreover, 3D printing has enabled the creation of custom and unique structures on demand, reducing the need for large production runs and excess inventory. This approach has also allowed for greater customization, with structures being tailored to individual requirements and preferences.

Furthermore, 3D printing has the potential to reduce waste in the construction industry by creating products with less material waste. The technology also enables the use of new materials, including sustainable and eco-friendly materials, for construction production.

51. How can 3D printing be used in the education industry?

3D printing is a valuable tool in the education industry as it helps students better understand complex concepts, particularly in the fields of science, technology, engineering, and math (STEM). The technology allows students to create tangible models of their ideas, enabling them to learn through a hands-on experience.

In addition to this, 3D printing encourages creativity and problem-solving skills as students can design and create their own objects from scratch. It also enables them to visualize and understand how the design process works and how products are created.

Moreover, 3D printing also allows for the creation of more accurate and detailed models compared to traditional methods, which helps students better understand the intricacies of a subject. It can also be used to create customized educational aids such as anatomical models or prototypes of scientific concepts.

Furthermore, 3D printing can also teach important technical skills such as computer-aided design (CAD) and 3D modeling, which are valuable in many fields. This technology can help bridge the gap between theoretical learning and practical experience, ultimately leading to a more well-rounded education for students.

52. How can 3D printing be used in the jewelry industry?

3D printing has transformed the jewelry industry by enabling the creation of intricate and unique designs that were previously impossible with traditional methods. The technology allows for the rapid production of jewelry, making it easier to produce custom-made pieces for clients.

Jewelry designers can use 3D printing to create prototypes quickly and efficiently, enabling them to test out different designs before committing to production. This allows for more experimentation in the design process, leading to more creative and unique pieces.

Moreover, 3D printing allows for the production of complex geometries and intricate patterns that would be difficult to achieve with traditional methods. This opens up new possibilities for designers to create pieces that were once impossible to make.

3D printing also reduces waste in the jewelry production process, as only the required amount of material is used. This is particularly important in the precious metal industry, where material costs are high.

Finally, 3D printing enables the production of unique, one-of-a-kind pieces of jewelry. This is especially valuable in the luxury market, where exclusivity is highly valued.

53. What are the challenges of 3D printing in mass production?

While 3D printing has many benefits for mass production, it also comes with several challenges. One of the biggest challenges is speed; 3D printing is generally slower than traditional manufacturing methods, which can limit its use in mass production. However, advances in technology are addressing this issue and making 3D printing faster and more efficient.

Another challenge is scalability; traditional manufacturing methods can produce large quantities of products quickly, while 3D printing is limited by the size of the printer and the speed of the printing process. This makes it difficult to scale up production to meet large demand.

Quality control is also a challenge in 3D printing for mass production, as each printed part may have minor variations that can affect the final product’s quality. This requires careful monitoring and testing to ensure consistent quality across all products.

Additionally, the cost of 3D printing can be higher than traditional manufacturing methods, particularly for larger production runs. This makes it less cost-effective for mass production in some cases.

Finally, the limited range of materials available for 3D printing is also a challenge for mass production. While there are many materials available for 3D printing, they may not be suitable for all products. This limits the range of products that can be produced using 3D printing in mass production.

54. How can 3D printing be used in rapid prototyping?

3D printing is an ideal technology for rapid prototyping as it allows for the quick production of functional prototypes. It enables designers and engineers to quickly create physical models of their designs, allowing for testing and validation before committing to production.

The ability to quickly iterate on designs is a significant advantage of 3D printing for rapid prototyping. Designers can easily make changes to their models and print new iterations in a matter of hours, allowing them to test different variations and refine their designs quickly. This leads to faster product development cycles and ultimately shorter time-to-market.

Moreover, 3D printing also allows for the production of highly detailed and complex prototypes that are difficult or impossible to achieve with traditional methods. This enables designers to create more accurate representations of their designs, leading to better validation and testing results.

Another advantage of 3D printing in rapid prototyping is the ability to produce customized prototypes quickly and easily. This is particularly useful for industries such as healthcare and aerospace, where personalized products are in high demand.

Finally, 3D printing also allows for the production of functional prototypes that can be tested under real-world conditions. This enables engineers to validate their designs and make necessary adjustments before committing to production, ultimately leading to better quality products.

55. What is the role of 3D printing in the development of new products?

3D printing plays a critical role in the development of new products by enabling faster and more efficient product development cycles. The technology allows designers and engineers to quickly create functional prototypes, test them, and refine them before committing to production.

This leads to shorter time-to-market, enabling companies to respond more quickly to changing market demands and stay ahead of the competition. It also reduces the cost of product development by eliminating the need for expensive tooling and mold making required in traditional manufacturing methods.

Moreover, 3D printing also enables more design freedom and flexibility, allowing for the creation of complex geometries and intricate designs that would be difficult to achieve with traditional methods. This opens up new possibilities for product design and innovation.

Another advantage of 3D printing in product development is the ability to produce small production runs quickly and cost-effectively. This is particularly useful for niche markets or products that require customization.

Finally, 3D printing also enables more sustainable product development by reducing waste and minimizing the environmental impact of the product development process. This is becoming increasingly important in today’s world where sustainability is a critical concern.

56. What is the impact of 3D printing on supply chain management?

3D printing has the potential to revolutionize supply chain management by enabling more localized and on-demand production. The technology allows for the creation of products closer to the end-user, reducing the need for large-scale manufacturing and transportation.

This enables companies to reduce their reliance on global supply chains, which can be vulnerable to disruptions such as natural disasters, political instability, and pandemics. It also reduces lead times, enabling companies to respond more quickly to changing market demands.

Moreover, 3D printing also enables companies to produce smaller production runs cost-effectively, reducing the need for large inventories and minimizing the risk of excess inventory. This is particularly valuable in industries with short product life cycles or rapidly changing market demands.

Another advantage of 3D printing in supply chain management is the ability to produce customized products quickly and easily. This enables companies to respond to individual customer needs and preferences, leading to higher customer satisfaction and loyalty.57. What are the ethical implications of 3D printing?

The rise of 3D printing has raised several ethical concerns, particularly around intellectual property, privacy, and safety. One of the most significant ethical implications of 3D printing is its potential to facilitate copyright infringement and piracy. As 3D printing becomes more accessible, it becomes easier for individuals to reproduce and distribute copyrighted products without permission. This raises questions about intellectual property rights and the protection of creative works.

Another ethical concern with 3D printing is the potential for the technology to be used to create dangerous or illegal products, such as firearms or counterfeit goods. This raises questions about the regulation and control of 3D printing and the need for appropriate legal frameworks to manage the technology’s use.

58. What is the role of 3D printing in the circular economy?

3D printing has the potential to play a significant role in the circular economy by enabling more sustainable production and reducing waste. The circular economy is an economic model that aims to keep resources in use for as long as possible by minimizing waste and maximizing the value of resources.

One of the key benefits of 3D printing in the circular economy is the ability to produce products on-demand and closer to the end-user, reducing the need for large-scale manufacturing and transportation. This reduces the carbon footprint of production and transportation, ultimately leading to a more sustainable model of production.

Moreover, 3D printing also enables the production of products from recycled or upcycled materials, reducing the need for virgin materials and minimizing waste. This is particularly valuable in industries such as fashion and textiles, where waste is a significant problem.

Another advantage of 3D printing in the circular economy is the ability to repair and maintain products more easily. 3D printing can be used to create replacement parts or components for products that are no longer available, extending the lifespan of products and reducing the need for new products.

Finally, 3D printing also enables more localized and customized production, allowing products to be tailored to individual needs and preferences. This reduces the risk of overproduction and waste and ultimately leads to a more sustainable model of production.

59. How can 3D printing be used in disaster relief efforts?

3D printing has the potential to play a critical role in disaster relief efforts by enabling the rapid production of essential items such as medical supplies, shelter, and food.

One of the key benefits of 3D printing in disaster relief efforts is the ability to produce essential items on-site and on-demand. This eliminates the need for lengthy supply chains and enables aid workers to respond more quickly and efficiently to emergencies.

Moreover, 3D printing also enables the production of customized items that are tailored to the specific needs of a disaster situation. For example, 3D printing can be used to create medical supplies such as prosthetics or dental implants that are customized to fit individual patients.

Another advantage of 3D printing in disaster relief efforts is the ability to produce items using locally available materials. This reduces the need for costly imports and makes it easier to produce essential items in remote or underdeveloped areas.

Finally, 3D printing also has the potential to reduce waste in disaster relief efforts by enabling the production of items that are designed to be reused or recycled. This leads to a more sustainable model of disaster relief that is better for the environment and more cost-effective in the long run.

60. How can 3D printing be used for creating sustainable products?

3D printing has the potential to play a significant role in creating sustainable products by enabling more localized and customized production, reducing waste, and minimizing the environmental impact of production and transportation.

One of the key benefits of 3D printing in creating sustainable products is the ability to produce products closer to the end-user, reducing the need for large-scale manufacturing and transportation. This leads to a more sustainable model of production that is better for the environment and reduces the carbon footprint of production and transportation.

Moreover, 3D printing also enables the production of products from recycled or upcycled materials, reducing the need for virgin materials and minimizing waste. This is particularly valuable in industries such as fashion and textiles, where waste is a significant problem.

Another advantage of 3D printing in creating sustainable products is the ability to produce customized products quickly and easily. This enables products to be tailored to individual needs and preferences, reducing the risk of overproduction and waste.

Finally, 3D printing also enables the production of products that are designed for disassembly and repair, extending the lifespan of products and reducing the need for new products. This leads to a more circular model of production that is better for the environment and more cost-effective in the long run.

61. What is the impact of 3D printing on traditional manufacturing processes?

3D printing has the potential to disrupt traditional manufacturing processes by enabling faster and more efficient production, reducing the need for tooling and molds, and enabling the production of complex geometries and customized products.

One of the key benefits of 3D printing is the ability to produce products on-demand and closer to the end-user, reducing the need for large-scale manufacturing and transportation. This leads to shorter lead times and faster time-to-market, enabling companies to respond more quickly to changing market demands.

Moreover, 3D printing also eliminates the need for expensive tooling and molds required in traditional manufacturing methods. This reduces the cost of production and makes it easier for small businesses and startups to enter the market.

Another advantage of 3D printing is the ability to produce highly complex geometries and intricate designs that would be difficult or impossible to achieve with traditional methods. This opens up new possibilities for product design and innovation.

Finally, 3D printing also enables the production of customized products quickly and easily. This is particularly valuable in industries such as healthcare and aerospace, where personalized products are in high demand.

However, 3D printing also has some limitations compared to traditional manufacturing methods. The technology is still limited in terms of the range of materials and products that can be produced, which may limit its use in certain industries. It also requires significant investment in equipment and training, which may be a barrier for some companies.

62. How can 3D printing be used in the creation of customized medical devices?

3D printing has the potential to revolutionize the creation of customized medical devices by enabling the production of patient-specific devices quickly and cost-effectively.

One of the key benefits of 3D printing in the creation of customized medical devices is the ability to produce patient-specific devices that are tailored to the individual’s unique anatomy. This leads to better patient outcomes and reduces the risk of complications associated with poorly fitting devices.

Moreover, 3D printing also enables the production of highly complex geometries and intricate designs that are difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for the design and functionality of medical devices.

Another advantage of 3D printing in the creation of customized medical devices is the ability to produce small production runs cost-effectively. This is particularly valuable in the development of new medical devices, where small-scale testing is required before committing to large-scale production.

Finally, 3D printing also enables the production of devices using biocompatible materials, reducing the risk of allergic reactions or other adverse events.

However, 3D printing also poses some challenges in the creation of customized medical devices. The technology is still limited in terms of the range of materials and products that can be produced, which may limit its use in certain applications. It also requires significant investment in equipment and training, which may be a barrier for some companies.

63. What is the role of 3D printing in the field of dentistry?

3D printing has the potential to transform the field of dentistry by enabling the production of patient-specific dental devices, such as aligners, dentures, and crowns, quickly and cost-effectively.

One of the key benefits of 3D printing in dentistry is the ability to produce patient-specific devices that are tailored to the individual’s unique anatomy. This leads to better patient outcomes and reduces the risk of complications associated with poorly fitting devices.

Moreover, 3D printing also enables the production of highly accurate and detailed dental models, allowing dentists and orthodontists to plan and prepare treatments more effectively.

Another advantage of 3D printing in dentistry is the ability to produce small production runs cost-effectively. This is particularly valuable in the production of dental implants and other devices that are customized to the individual patient’s needs.

Finally, 3D printing also enables the production of devices using biocompatible materials, reducing the risk of allergic reactions or other adverse events.

64. What is the potential for 3D printing in the creation of living tissue?

3D printing has the potential to revolutionize the field of tissue engineering by enabling the creation of living tissue that can be used for transplantation or research purposes.

One of the key benefits of 3D printing in tissue engineering is the ability to create highly complex and intricate tissue structures that mimic the natural structure of living tissue. This allows for better integration of the tissue with the body and improves the functional outcomes of transplants.

Moreover, 3D printing also enables the production of patient-specific tissue structures, reducing the risk of rejection and other adverse events.

Another advantage of 3D printing in tissue engineering is the ability to create tissue structures using multiple materials, such as scaffolds and biological materials, that can be designed to support the growth and development of living tissue.

Finally, 3D printing also enables the creation of tissue structures more quickly and cost-effectively than traditional tissue engineering methods, such as cell culturing and tissue growth.

However, 3D printing also poses some challenges in tissue engineering. The technology is still in the early stages of development, and the range of materials and tissue types that can be produced is still limited. Moreover, the production of living tissue using 3D printing requires highly specialized equipment and training, which may be a barrier for some researchers and medical practitioners.

65. How can 3D printing be used in the creation of art and design products?

3D printing has the potential to transform the field of art and design by enabling the creation of highly complex and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods.

One of the key benefits of 3D printing in art and design is the ability to create highly customized and unique designs that are tailored to individual needs and preferences. This opens up new possibilities for artistic expression and creativity.

Moreover, 3D printing also enables the production of highly complex and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods, such as subtractive manufacturing or molding. This allows artists and designers to push the boundaries of what is possible in terms of design and functionality.

Another advantage of 3D printing in art and design is the ability to produce small production runs cost-effectively. This is particularly valuable in the production of art and design products that are customized or limited edition, enabling artists and designers to create unique and highly sought-after products.

Finally, 3D printing also enables the use of a wide range of materials, including new and experimental materials, that can be used to create highly customized and unique designs.

66. What is the potential for 3D printing in the creation of low-cost housing?

3D printing has the potential to transform the construction industry by enabling the creation of low-cost housing that can be built quickly and efficiently using 3D printing technology.

One of the key benefits of 3D printing in low-cost housing is the ability to produce housing units quickly and cost-effectively. This is particularly valuable in developing countries and areas affected by natural disasters, where there is a shortage of affordable housing.

Moreover, 3D printing also enables the creation of housing units that are highly customizable and tailored to the needs of individual families and communities. This opens up new possibilities for the design and functionality of low-cost housing.

Another advantage of 3D printing in low-cost housing is the ability to use locally available materials, such as soil, sand, and clay, reducing the need for expensive imports and making it easier to produce affordable housing in remote or underdeveloped areas.

Finally, 3D printing also has the potential to reduce waste in the construction industry by enabling the production of housing units that are designed for disassembly and reuse.

However, 3D printing also poses some challenges in low-cost housing. The technology is still in the early stages of development, and the range of materials and designs that can be produced is still limited. Moreover, the use of 3D printing technology requires highly specialized equipment and training, which may be a barrier for some construction workers and builders.

67. How can 3D printing be used in the creation of wearable technology?

3D printing has the potential to revolutionize the field of wearable technology by enabling the creation of highly customized and functional designs that are tailored to individual needs and preferences.

One of the key benefits of 3D printing in wearable technology is the ability to produce customized designs quickly and cost-effectively. This enables wearable technology to be tailored to the individual’s unique anatomy and preferences, improving comfort and functionality.

Moreover, 3D printing also enables the production of highly complex and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for the design and functionality of wearable technology.

Another advantage of 3D printing in wearable technology is the ability to produce small production runs cost-effectively. This is particularly valuable in the production of customized or limited edition wearable technology products, enabling designers and manufacturers to create unique and highly sought-after products.

Finally, 3D printing also enables the use of a wide range of materials, including new and experimental materials, that can be used to create highly customized and functional designs.

However, 3D printing also poses some challenges in wearable technology. The technology is still limited in terms of the range of materials and products that can be produced, which may limit its use in certain applications. It also requires significant investment in equipment and training, which may be a barrier for some designers and manufacturers.

68. What is the impact of 3D printing on intellectual property rights?

The impact of 3D printing on intellectual property rights is a complex and controversial issue.

One of the key challenges of 3D printing is the ease with which it allows individuals to create and reproduce objects that are protected by intellectual property rights, such as patents, copyrights, and trademarks. This raises concerns about the potential for infringement of intellectual property rights and the impact on innovation and creativity.

Moreover, 3D printing also poses challenges for the enforcement of intellectual property rights, as it is difficult to monitor and regulate the use of 3D printing technology by individuals and small-scale manufacturers.

On the other hand, 3D printing also has the potential to facilitate innovation and creativity by enabling individuals and small-scale manufacturers to produce and customize products quickly and cost-effectively. This opens up new possibilities for individual expression and personalization, and can drive innovation in the design and production of new products.

69. What are the challenges of 3D printing in the creation of complex geometries?

While 3D printing has the potential to create highly complex and intricate geometries, it also poses some challenges in the creation of complex designs.

One of the key challenges of 3D printing in the creation of complex geometries is the need for support structures, which are necessary to support overhanging or bridging sections of the design. These support structures can be difficult to remove after printing and may leave marks or damage on the final product.

Moreover, 3D printing also poses challenges in the production of intricate designs with small details or features. The resolution of the printing process may be limited, making it difficult to reproduce very small or fine details accurately.

Another challenge of 3D printing in the creation of complex geometries is the need for precise calibration of the printing process. Any deviation or variation in the printing process can lead to errors or defects in the final product, which can be particularly problematic in complex designs.

Finally, 3D printing also poses challenges in the selection and optimization of materials for complex designs. The properties and characteristics of the material can affect the quality and functionality of the final product, and may limit the range of materials that can be used for complex designs.

70. How can 3D printing be used in the creation of consumer goods?

3D printing has the potential to transform the field of consumer goods by enabling the creation of highly customized and functional designs that are tailored to individual needs and preferences.

One of the key benefits of 3D printing in consumer goods is the ability to produce customized designs quickly and cost-effectively. This enables consumer goods to be tailored to the individual’s unique preferences and needs, improving comfort and functionality.

Moreover, 3D printing also enables the production of highly complex and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for the design and functionality of consumer goods.

Another advantage of 3D printing in consumer goods is the ability to produce small production runs cost-effectively. This is particularly valuable in the production of customized or limited edition consumer goods, enabling designers and manufacturers to create unique and highly sought-after products.

Finally, 3D printing also enables the use of a wide range of materials, including new and experimental materials, that can be used to create highly customized and functional designs.

However, 3D printing also poses some challenges in the creation of consumer goods. The technology is still limited in terms of the range of materials and products that can be produced, which may limit its use in certain applications. It also requires significant investment in equipment and training, which may be a barrier for some designers and manufacturers.

71. What are the different types of 3D printing technologies and how do they work?

There are several different types of 3D printing technologies, each with its own strengths and weaknesses. Here are some of the most common types of 3D printing technologies and how they work:

Fused Deposition Modeling (FDM): This is the most common type of 3D printing technology. It works by melting a plastic filament and extruding it through a nozzle to create the object layer by layer.

- Stereolithography (SLA): This type of 3D printing uses a laser to cure a liquid resin, creating the object layer by layer. It produces highly detailed and accurate objects.

- Selective Laser Sintering (SLS): This type of 3D printing uses a laser to sinter a powder material, such as nylon or metal, creating the object layer by layer. It is commonly used in industrial applications.

- Digital Light Processing (DLP): This type of 3D printing uses a projector to cure a liquid resin, creating the object layer by layer. It produces highly detailed and accurate objects.

- Binder Jetting: This type of 3D printing uses a liquid binder to bind together layers of powder material, creating the object layer by layer. It is commonly used in the production of ceramics and metal parts.

- Material Jetting: This type of 3D printing uses inkjet technology to deposit droplets of material onto a build platform, creating the object layer by layer. It produces highly detailed and accurate objects.

- Electron Beam Melting (EBM): This type of 3D printing uses an electron beam to melt a metal powder, creating the object layer by layer. It is commonly used in the production of metal parts for aerospace and medical applications.

72. What is the role of computational design in 3D printing?

Computational design plays a crucial role in 3D printing by enabling the creation of highly complex and optimized designs that would be difficult or impossible to achieve with traditional design methods.

One of the key benefits of computational design in 3D printing is the ability to optimize designs for specific performance requirements, such as weight reduction, strength, or flexibility. This is particularly valuable in the production of parts and components for aerospace, automotive, and medical applications, where performance and reliability are critical.

Moreover, computational design also enables the creation of highly complex geometries and structures that would be difficult or impossible to produce with traditional design methods. This opens up new possibilities for the design and functionality of products and components.

Another advantage of computational design in 3D printing is the ability to produce designs quickly and cost-effectively. This is particularly valuable in the production of customized or limited edition products, enabling designers and manufacturers to create unique and highly sought-after products.

Finally, computational design also enables the use of a wide range of materials, including new and experimental materials, that can be used to create highly customized and functional designs.

However, computational design also poses some challenges in 3D printing. The complexity and computational requirements of the design process may require specialized software and training, which can be a barrier for some designers and manufacturers. Moreover, the optimization of designs for 3D printing may require a different approach to traditional design methods, which may require a shift in design thinking and practice.

73. How can 3D printing be used in the creation of synthetic organs?

3D printing has the potential to revolutionize the field of synthetic organ creation by enabling the production of highly customized and functional organs that are tailored to individual needs and preferences.

One of the key benefits of 3D printing in synthetic organ creation is the ability to produce customized designs quickly and cost-effectively. This enables synthetic organs to be tailored to the individual’s unique anatomy and requirements, improving comfort and functionality.

Moreover, 3D printing also enables the production of highly complex and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for the design and functionality of synthetic organs.

Another advantage of 3D printing in synthetic organ creation is the ability to produce small production runs cost-effectively. This is particularly valuable in the production of customized or limited edition synthetic organs, enabling designers and manufacturers to create unique and highly sought-after products.

Finally, 3D printing also enables the use of a wide range of materials, including new and experimental materials, that can be used to create highly customized and functional designs.

However, 3D printing also poses some challenges in synthetic organ creation. The technology is still limited in terms of the range of materials and products that can be produced, which may limit its use in certain applications. It also requires significant investment in equipment and training, which may be a barrier for some researchers and manufacturers.

74. What are the challenges of 3D printing in the creation of high-strength materials?

While 3D printing has the potential to create high-strength materials, it also poses some challenges in the creation of these materials.

One of the key challenges of 3D printing in the creation of high-strength materials is the need for precise control over the printing process. Any deviation or variation in the printing process can lead to errors or defects in the final product, which can affect the strength and durability of the material.

Moreover, 3D printing also poses challenges in the selection and optimization of materials for high-strength applications. The properties and characteristics of the material can affect the quality and functionality of the final product, and may limit the range of materials that can be used for high-strength applications.

Another challenge of 3D printing in the creation of high-strength materials is the need for post-processing and finishing of the final product. This may involve additional treatments, such as heat treatment or chemical processing, to improve the strength and durability of the material.

Finally, 3D printing also poses challenges in the validation and certification of high-strength materials for use in safety-critical applications, such as aerospace or medical devices. The testing and validation of 3D-printed materials may require new approaches and standards to ensure the safety and reliability of the final product.

75. What is the role of 3D printing in the creation of nanomaterials?

3D printing has the potential to play a significant role in the creation of nanomaterials, which are materials with unique properties and characteristics at the nanoscale level.

One of the key benefits of 3D printing in the creation of nanomaterials is the ability to produce complex geometries and structures at the nanoscale level. This enables the creation of highly customized and functional nanomaterials for a range of applications, including energy, electronics, and medicine.

Moreover, 3D printing also enables the creation of multi-material and hybrid nanomaterials, which combine different materials and properties to achieve new and unique functionalities. This opens up new possibilities for the design and functionality of nanomaterials.

Another advantage of 3D printing in the creation of nanomaterials is the ability to produce small production runs cost-effectively. This is particularly valuable in the production of customized or limited edition nanomaterials, enabling researchers and manufacturers to create unique and highly sought-after products.

Finally, 3D printing also enables the use of a wide range of materials, including new and experimental materials, that can be used to create highly customized and functional nanomaterials.

However, 3D printing also poses some challenges in the creation of nanomaterials. The technology is still limited in terms of the range of materials and products that can be produced at the nanoscale level, which may limit its use in certain applications. It also requires significant investment in equipment and training, which may be a barrier for some researchers and manufacturers.

76. How can 3D printing be used in the creation of new materials?

3D printing, also known as additive manufacturing, has revolutionized the way we create objects. It has a vast potential for the creation of new materials. 3D printing can be used to create materials with new and unique properties that cannot be achieved using traditional manufacturing techniques. This is possible because 3D printing allows for the creation of complex geometries that cannot be produced using traditional manufacturing techniques. This enables the creation of materials with different shapes, sizes, and properties.

In 3D printing, materials can be mixed or combined to create composites with unique properties. For instance, a material can be mixed with another to create a hybrid that exhibits better strength and durability. Furthermore, 3D printing enables the creation of materials with different textures, such as porous or flexible materials.

In addition, 3D printing can be used to create new materials that can perform specific functions. For example, scientists have used 3D printing to create new materials that can capture carbon dioxide from the air, making them ideal for use in carbon capture technology. The potential for 3D printing in the creation of new materials is vast, and it is only a matter of time before we see the full extent of what is possible.

77. What is the potential for 3D printing in the creation of living organs?

The creation of living organs using 3D printing has been a significant topic of interest in the medical industry. 3D printing enables the creation of complex geometries that can mimic the structure of human organs. This has the potential to revolutionize the medical industry and save countless lives.

One of the major advantages of using 3D printing to create living organs is that it can eliminate the need for organ donors. This is because the organs can be created using the patient’s own cells, reducing the risk of rejection by the immune system. 3D printing can also be used to create organs that are specifically tailored to an individual’s needs, increasing the chances of success during transplantation.

Researchers have already made significant progress in the creation of living organs using 3D printing. Scientists have used 3D printing to create functional heart valves, ears, and blood vessels, among other organs. While there are still many challenges to overcome, the potential for 3D printing in the creation of living organs is immense and holds the promise of transforming the medical industry.

78. What is the role of 3D printing in the creation of artificial intelligence?

Artificial intelligence (AI) is a rapidly growing field that has the potential to transform many aspects of our lives. 3D printing can play a significant role in the creation of AI by enabling the creation of custom components and structures.

One area where 3D printing can be used in the creation of AI is in the creation of robotic components. 3D printing allows for the creation of complex geometries and customized designs that can improve the performance of robots. For instance, 3D printing can be used to create lightweight and durable parts for robots, making them more agile and efficient.